MDF Storing and Processing

Transport and storage

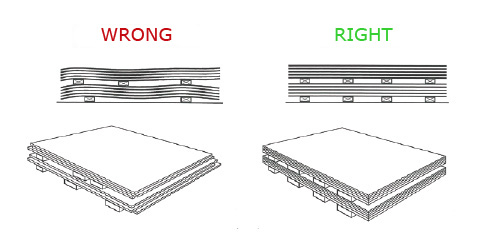

To preserve the flatness of MDF (Medium Density Fiberboard) Design, correct transport and storage is required during the various processing phases. MDF Design panels can become permanently

deformed through improper handling or stacking, e.g. when not supported by flat pallets or a sufficient number of supporting blocks:

- MDF Design panels are best stacked horizontally in packs, preferably on pallets or on dry stacked beams (70 x 70 mm or 90 x 90 mm).

- On potentially damp surfaces, a waterproof foil, e.g. polyethylene foil, is installed before the panels are stacked on it.

- When using stacked beams, they must be of equal thickness and spaced no more than 800mm apart. For panels less than 15mm thick it is recommended to use a greater number of stacked

beams. The sides of the panels shall project no more than 200mm from the outer stacked beams.

- The stacked beams are placed perfectly on top of each other, so that they support each other.

Figure 1: Schematic representation of incorrectly and correctly positioned stacked beams

Sawing

While working with MDF, decorative side panels must always be turned down to get a better line of cut and to prevent cracking paint. Boards are sawed by digital or format saw.

Always make sure to use sufficiently sharp tools to prevent cracking of the paint or MDF. When sawing MDF, the panel material must be passed across the saw blade at a sufficiently high feed rate:

- At too low a feed rate, the saw blade teeth will not cut, but instead crush and rub down on the panel material, whereby ‘burning’ may occur and fine dust is generated.

- At too high a feed rate, the sawed edges will be of poorer quality, noticeable from a fraying saw cut.

Drilling

For drilling MDF panels, standard drills and speeds of approx. 3500 r.p.m. are recommended, which allows high quality drilled holes with limited material accumulation on the rear side to

be obtained. To prevent material tearing on the rear side in case of drilled through holes, it is recommended to drill half of the hole depth on either side of the panel.